3D-Printing of Dual-Curing Urethane Elastomers

Abstract

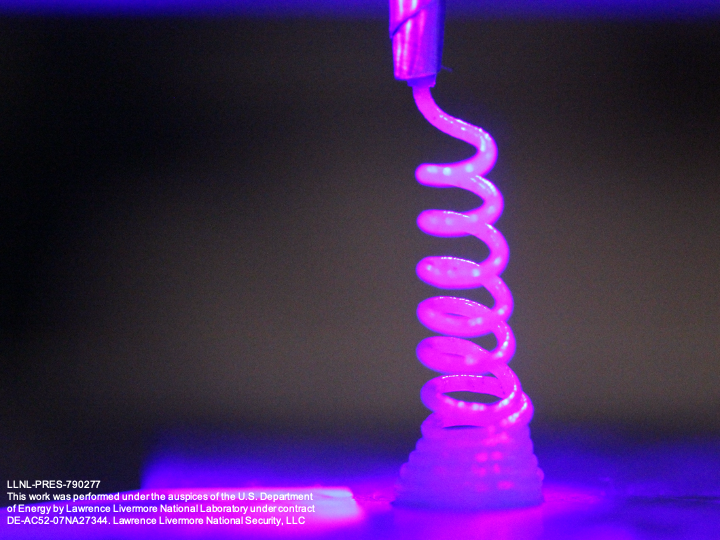

Direct-ink-writing (DIW) is an Additive Manufacturing (AM) technique that provides a versatile approach to fabricating arbitrarily shaped objects by exploiting the shear-thinning properties of polymeric-based inks. One major drawback of DIW is that shear-thinning inks are limited to a maximum height before the combined weight of additionally deposited layers exceeds the yield stress of the underlying layers and causes the material to flow.

Previous methods to combat this drawback have included intermittent or continuous exposure of the process to ultra-violet (UV) radiation to cure the material in place. However, these approaches require specific parameters that limit the UV-curable inks to specific applications and do not address the challenges associated with printing high-aspect-ratio objects. Here, we report a stepwise UV and heat curing process that facilitates DIW of a range of inks with varying rheological properties and that is no longer dimensionally limited by a yield stress. This stepwise curing process is enabled by small amounts of acrylates that cure to the back of the functionalized urethane prepolymers to promote rapid gelation in the object during extrusion, and a post thermal-curing step of the major urethane components once printing is complete. This method of fabrication effectively eliminates dimensional constraints of objects during fabrication, as well as expands the rheological range of printable inks.

Howell, Brian M., et al. “Spatially Controlled 3D Printing of Dual‐Curing Urethane Elastomers.” Advanced Materials Technologies 7.3 (2022): 2100700.

This work was performed under the auspices of the U.S. Department of Energy by Lawrence Livermore National

Laboratory under Contract DE-AC52-07NA27344.

LLNL-ABS-795840