Modeling, simulation and machine learning for rapid process control of multiphase flowing foods

Abstract

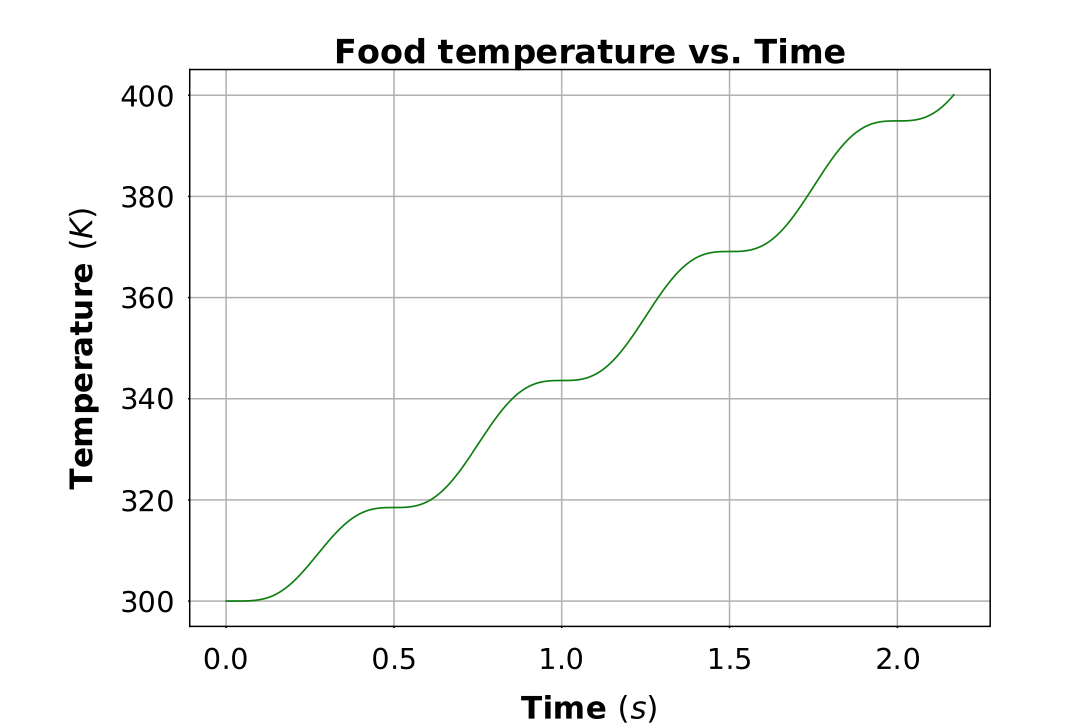

Across many modern industries, as technologies have matured, the use of more complex processes involving multiphase materials has increased. In the food industry, multiphase fluids are now relatively wide-spread, in particular, because of the desire to have faster throughput for large-scale food production. In many cases involving transport, such materials consist of a fluidized binder material with embedded particles. As one increases the volume fraction of particles, a corresponding increase in effective overall viscosity occurs. Often, during the process, the material must be heated, for example, to ensure food safety, induce pasteurization, sterilization, etc. For real-time control, this requires rapidly computable models to guide thermal processing, for example by applied electrical induction. In the present analysis, models are developed for the required heating field (electrically induced) and pressure gradient needed in a pipe to heat a multiphase material to a target temperature and to transport the material with a prescribed flow rate.